INDUSTRIAL SPRING (25-28.03.2025)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

IPOsystem

- ul. Rudzka 8, 44-200 RYBNIK, Poland

- +48 662 818 392

- iposystem@uibs.com.pl

- www.iposystem.com

Description

IPOsystem is a digital production manager who independently manages employees and machines in the halls, without the participation of planners and direct supervision personnel, ensuring timely execution of production orders with the maximum use of available resources.

IPOsystem makes real-time decisions regarding the sequence of implementation and selection of resources for individual technological activities. Each employee/team of employees, after reporting readiness to work in the system, immediately receives an order to perform the optimal technological operation at a given moment. The system only issues works that can be carried out at a given moment, indicating precisely the number of the production order, the workstation where the work should be performed, technological details of the operation and the place where the necessary materials, semi-finished products and tools are located. The preparation of these materials, semi-finished products and tools is also controlled by the system. Each time an employee finishes work in IPOsystem, the next system decision is calculated and a command optimized for that moment is issued. Thanks to decision-making algorithms, the entire process of calculating and issuing each task takes no longer than 5 seconds.

In this way, each employee in a factory controlled by IPOsystem works in the "Work - report - work - report - .... - work - report" procedure.

Such operation of the system is possible only because the calculations of the release of subsequent works are carried out in real time, without the scheduling process!

Employees interact with the system using terminals, tablets, smartphones, displays of machine controllers, personal computers, and in the near future augmented reality and voice commands. Through them, IPOsystem transmits autonomous decisions and enables providing additional reports and information. The system also enables the collection and use of data directly from machines (IoT) and independent control of machines and robots in processes carried out without human participation.

The system continuously calculates the production completion date for each order, informs managers about works that are carried out longer (slower) than the applicable standard, and indicates "bottlenecks" in the process.

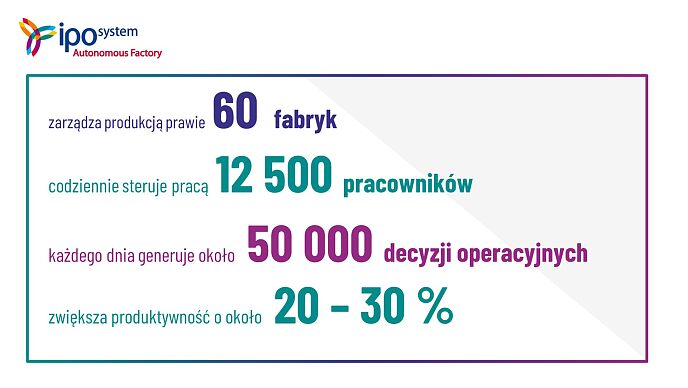

IPOsystem operates in nearly 60 factories in Poland, controlling the work of over 12,000 employees and generating approximately 50,000 operational decisions per day. IPOsystem increases production efficiency by as much as 15-30%.

Download

-

58647-folder-tryptyk-EN-www.pdffile size: 3.23 MB

-

58647-folder-tryptyk-PL-www.pdffile size: 3.49 MB

Products

• Automation of operational decisions through the ADS decision-making engine

• Resource work time management

• Management of multi-level technology (BOM + BOO)

• Generating production orders (incl. automatically)

• Management of production orders and deadlines

• Automatic balancing of material needs (MRP II)

• Balancing work needs (man hours and machine hours)

• Direct management of production resources (people and machines - IoT)

• Support for production cells

• Continuous supervision of production progress - MES

• Identification of production details and traceability

• Autonomous warehouse management

• Management of collection and storage fields

• Production logistics, including autonomous management of internal transport

• Tool management support

• Autonomous management of quality control

• Maintenance management (with the possibility of decision automation)

• Calculation of technical production costs

• Simulations and scenarios

• Data analysis of orders, works, resources, settlement of working time

• Analysis of production costs and valuation

• Bottleneck analysis and system control

• Data exchange with any ERP and other systems