News

Wittmann joins Plastpol with its innovative EcoPower DC injection molding machine. Electricity from photovoltaics is used to to operate the system

Solar batteries installed on company roofs generate on-site electricity, for costs saving and improving environmental protection. Wittmann offers the answer the question related to direct current generated by solar cells; now DC can be effectively used to directly operate injection molding systems.

The use of DC power to power the injection moulding machine has many advantages, so Wittmann has taken development steps to promote this technology. On the one hand, energy costs can be kept low with the use of direct solar energy. On the other hand, DC power can be easily stored in conventional batteries, thus it can be perfectly used to cover expensive power peaks and increase security of supply. By using direct current technology, CO2 emissions can be reduced by increasing energy efficiency.

Plastpol showcases the EcoPower 180/750+ B8X injection molding machine used to produce PP bodies made on a mold from the Austrian Kunststofftechnik Grabher GmbH. The details will be removed from the mould by a Wittmann WX142 robot, also DC powered. The robot will be powered by a connection on the EcoPower DC injection molding machine equipped with a system for energy recovery from braking movements. Rnergy recovered is transfmitted to the injection molding machine.

In order to present direct current technology to visitors live, the machine will be operated independently of the expo centre’s power grid through a solar energy storage system consisting of the latest technology of ecological salt batteries from Innovenergy. The battery has a total capacity of 45 kWh, which is sufficient for continuous operation of the machine throughout the entire 8-hour shift.

The DC injection molding machine is not the only Polish premiere of Wittmann during Plastpol; just a few months after the world premiere, the Primus series robot with the latest R9 control will be presented. PRIMUS robots are already well known to Wittmann customers and valued and willingly purchased to complement simpler machine automation systems. Robots’ clamping force - up to 400t. Primus robots offer attractive price and reliable design, they are a very good solution for "take and put away" applications. A Primus 116 robot is displayed at the epxo stand.

Of course, Wittmann cannot go without peripheral devices; this year, the company decided to put one of the product groups into a limelight. Wittmann is one of Europe’s largest manufacturers of thermostatic devices; the portfolio includes a very wide range of devices. We can easily select a right thermostat for a given application. Selected models will be presented during the expo,

an among them Wittmann Tempro Basic C120 - Thermostat for a pump with capacity of 200 l/min, operation with large moulds possible, Wittmann Tempro D140 EcoDrive - a device with an electric servo motor drive. The use of energy-saving thermostat drives is the next stage in optimising and reducing energy consumption in plastics processing. Thermostats with EcoDrive make it possible to reduce energy consumption by up to 40% compared to conventional thermostats. The company cares not only about the devices, but also about the work conditions; Wittmann Tempro DeCalc is the example This specialised device, although it resembles a thermostat, is used to clean thermostated circuits, including injection molds. One millimeter thick lime acumulated on walls of a thermostatic circuit reduces heat transfer by approximately 10%, 2 mm thick deposit reduces heat transfer by 75%. This is why maintaining the proper quality of thermostat circuits is so important. In line with the company's motto "Everything from a single source", Wittmann can offer both thermostats and devices for cleaning cooling channels.

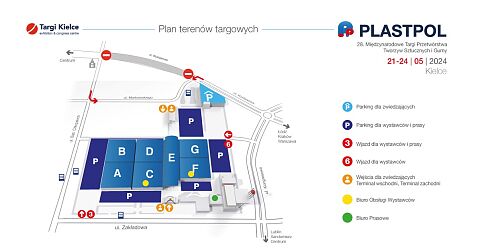

The Targi Kielce’s 28th International Fair of Plastics and Rubber Processing PLASTPOL is held in Targi Kielce from 21 to 24 May 2024. Registration for visitors and ticket sales continues on targikielce.pl/plastpol

/oprac. MŚ/