News

Sumitomo (SHI) Demag joins Plastpol 2024 with innovative energy-saving technologies

Sumitomo (SHI) Demag demonstrates that its all-electric IntElect platform is an excellent option for manufacturers of components in every market segment, including packaging, medical, automotive, electronics and consumer goods.

This year’s Plastpol is the company’s presentation platform - the expo stand F-19 is the display for the company’s applications. An energy-saving injection moulding machine from the IntElect series with a 180 tons clamping force will produce a technical bobbin in an 8-slot mould from Siemens. The cycle time is 13 seconds and a single piece weighs only 1.64 grams. The detail will be made of polyamide PA66 reinforced with 25% glass fibre supplied by BASF, therefore, the injection moulding machine will be equipped the higher abrasion-resistant injection unit, with a bimetallic cylinder.

The detail construction is also a challenge - irregular geometry and small size require extremely high precision and repeatability; the responsibility rests on the injection moulding machine to maintain the desired quality of the detail. However, such applications make IntElect series injection moulding machines best demonstrator of capabilities.

An SDR 22X robot will be integrated with the machine. The robot removes the details from the mould along with the tunnel gate, then the tunnel gate will be cut into smaller pieces and thrown into the grinder, and the detail will be transferred to the conveyor belt. The grinder and material feeder are supplied by Moretto.

Reflecting energy crisis, material costs, recyclability and productivity challenges faced by global polymer processors, Sumitomo (SHI) Demag has accelerated its strategic plans to expand its IntElect portfolio of machines into every market. Therefore, the company keeps developing its know-how in fully electric injection moulding machines, introducing new series and models of machines based on its own electric drives and rigid structure, ready to work in various conditions and in multiple industries, from medical to packaging.

The company’s proprietary direct, air-cooled drives make IntElect consume up to 20% less energy compared to conventional, fully electric injection moulding machines available on the market and 60% less electricity than hydraulic injection moulding machines. The firm can achieve high acceleration without batteries with direct drives in IntElect injection moulding machines. The IntElect injection moulding machine design also enables 100% braking energy recovery.

Braking energy storage in capacitors in the intermediate circuit allows energy reuse in the production process, thus reducing electricity consumption and production costs.

You will see the advantages of the fully electric IntElect series of machines at the Sumitomo (SHI) Demag expo stand in expo hall F, stand F-19.

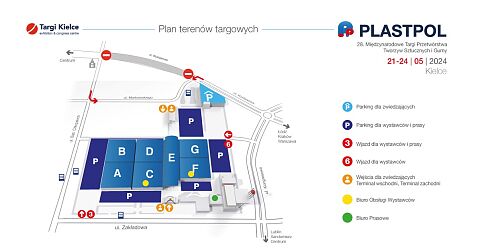

The Targi Kielce’s 28th International Fair of Plastics and Rubber Processing PLASTPOL is held in Targi Kielce from 21 to 24 May 2024. Registration for visitors and ticket sales continues on targikielce.pl/plastpol

Ed. /MŚ/