News

Wittmann Battenfeld with the latest solutions in injection technology and automation at the Plastpol trade fair

Their exhibition's focal point—at expo stand 6-08 in expo hall 6—will be the SmartPower Combimould injection moulding machine with a servo-electric injection unit, presented in an integrated, operational production system. The SmartPower 120/350h/130s machine combines the advantages of the hydraulic series (compactness and mould space) with the precision of the EcoPower electric series. The system was integrated with the W918 robot and a conveyor belt as part of the compact “Insider” system.

The technological process includes two-component moulding of a bottle opener from PC and TPE. The robot automatically positions the metal inserts and decorative foil and embeds them in the plastic. The product then goes to the second station, where a soft component is cast to improve the handle's ergonomics.

The material for production is prepared by the Aton plus dryer, located next to the injection moulding machine. The intuitive touch panel allows full process control, including temperature and dew point; the system provides direct material supply to two injection units.

Automation in the spotlight

Wittmann Battenfeld will also present modern solutions in the field of robotics and production automation; A special attraction will be the expo stand with the Primus 148T robot, where visitors can take a souvenir photo… sitting on the robot's horizontal axis. This is not only an effective form of promotion but also an excellent opportunity to familiarize yourself with the machine's design and capabilities. It is designed to work with injection molding machines with a clamping force of up to 9,000 kN and grippers weighing up to 35 kg.

Peripherals with intelligence and economy

The expo stand will also feature innovations in the field of peripherals - the company will showcase a central material handling system based on stainless steel Feedmax B feeders and a Codemax system with RFID control, which will enable the demonstration of the functionality of the Wittmann M8 network control – valued for its flexibility in large production installations.

The highlight - the WFC 120 system in terms of thermostating, which allows for precise control of temperature and flow in each cooling circuit (up to 120°C). Comparing the operation of manual and automatic valves will allow us to assess the real benefits of automation – including reduced losses and process stability. In combination with the Tempro plus EcoDrive system, energy savings of up to 70% are possible.

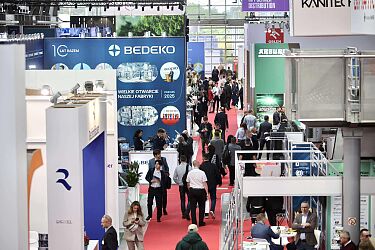

The presented technologies respond to the most important needs of modern production plants: efficiency, flexibility, precision, cost savings and sustainable development. It is worth getting to know them during the 29th International Fair of Plastics and Rubber Processing PLASTPOL, which will take place from 20 to 23 May 2025. Tickets - plastpol.com