News

STOM-TOOL 2024: FABA METAL offer - become familiar

FABA METAL is a leading manufacturer of standard and special cutting tools. today's rapidly evolving world sees cutting tools an essential element of industrial progress. Modern technologies not only increase efficiency, but also improve the precision and safety of production processes. Since 2008, FABA METAL has intensively expanded its range of tools. Their products have gained great recognition in various industries. At the tool design stage, qualified designers are can properly adjust the geometry to the required workpiece material and technological conditions. Particular emphasis on the tools quality translates into increased efficiency and durability, while reducing production costs; the latter is now becoming the main strategic point of many enterprises. The flagship products of FABA METAL - monolithic carbide cutters (roughing to finishing). Strength, durability and wear resistance, they enable cutting of high-hardness materials, which is crucial in the aviation and automotive industries. The new products include a comprehensive offer of milling cutters for machining of coated aluminium - this significantly increases the tool life against built-up edge formation.

Another new item FABA METAL has focused on is milling cutters for profile machining of steel, hardened steel and aluminium. Cutters from the TMB family, i.e. barrel cutters - the geometry had to be developed from scratch in order to increase the tools efficiency when high machining parameters and large material allowances are required. A much larger cutter radius compared to a ball cutter allows for a reduction in the number of passes, which shortens machining time.

Carbide drills are also available in the company's offer - in addition to typical solutions of 3xD, 5xD and 8xD drills for steel and non-ferrous metals, FABA specialises in the production of specialised designs of chamfering, step and profile drills to meet the requirements of a specific project.

The well-equipped machinery park capable of swift production and deliver of any the required tools. In mid-2023, the fully automated, integrated, maintenance-free AIMS system (ANCA Integrated Manufacturing System) was launched; which makes FABA the first company in the world to implement this type of solution. The advanced system is a pioneering, very innovative production system which pave the way for the future optimisation modern in cutting tool technology and provides comprehensive solutions for all toolmaking challenges. AIMS system is the future trend in production of monolithic tools, milling cutters, drills and reamers. Innovation trend has boosted faster and more precise production; the system increases productivity and repeatability of tools, maintaining a smooth production process. Production is carried out in batches, allowing 7 day-a-week work in a three-shift system. The production process is as automated at its maximum, throughout the process - moving tools between operations using a robot to fully automated tool measurement and process compensation and data management. AIMS ensures streamlined manufacturing - toolmaking processes is integrated with IT systems. This elevates toolmaking to the next level for increased production efficiency. The whole scheme translates into reduced production costs while maintaining the highest quality of products. FABA focuses on the quality and precision of its products, makes the most of cutting-edge measuring devices, including electronic and laser, to obtain the highest quality product. As a result, durable and aesthetic products that meet customer requirements are offered. The company adapts to the individual needs of the customer, creating complex and non-standard products. Product production begins in the design office, design, production, sales, delivery, service and professional advice are the motto of FABA. Specialists are open to all customer inquiries.

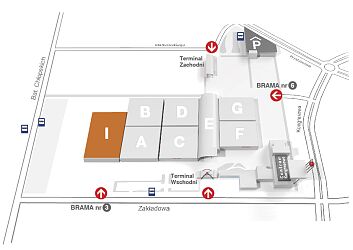

Exchange of technical ideas takes place during industry expo. We look forward to seeing you at the FABA expo stand at the Kielce exhibition and congress centre - March 2024 - STOM-TOOL A expo hall, expo stand – A-40. Expo is also a unique opportunity to strengthen good relationships with customers and present many new products.

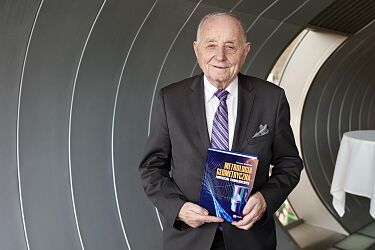

These factors are worth considering when choosing a company or business partner. Modern companies such as FABA SA often offer better and more advanced solutions. At the same time they offer an individual approach to the client in a responsible manner and in accordance with broadly defined values and good practices. We are a partner which provides long-term cooperation. In return we guarantee convenient solutions. We invite all our customers to become familiar with FABA's offer on the company's website www.fabametal.pl.and on Facebook.

![FABAMETAL-2.jpg [1.02 MB]](https://www.targikielce.pl/storage/image/core_files/2024/1/25/94b02a02892d93f95e12189270121933/default/preview/FABAMETAL-2.jpg)

![FABAMETAL-22.jpg [84.49 KB]](https://www.targikielce.pl/storage/image/core_files/2024/1/25/ec5867356fa86157abf2646152d41119/default/preview/FABAMETAL-22.jpg)

![AIMS-FABA.jpg [306.44 KB]](https://www.targikielce.pl/storage/image/core_files/2024/1/25/54c426168bd5f63e6fad93474a64a9a0/default/preview/AIMS-FABA.jpg)