News

Rapid prototyping of metals at the STOM Expo in Kielce

Rapid prototyping of metal materials - the process used in engineering to quickly create models or parts from metal. Rapid prototyping involves advanced technologies such as 3D metal printing and CNC machining to produce prototypes and small batches of metal parts quickly and efficiently, without the need to use traditional production methods, which can be time-consuming and expensive. This allows engineers to test their ideas, introduce corrections and accelerate the product development.

Tuesday's seminar on "Rapid prototyping of metal materials" brought together experts from the Upper Silesian Institute of Technology who discussed the possibilities of prototyping in detail. Marek Węglowski explained the importance of this modern technology for many spheres of life; - In medicine, prototyping is used in printing tailor-made prostheses, e.g. jaw or hip joints. Each prosthesis is properly adjusted to the patient - said Marek Węglowski. – Prototyping makes it possible to print a unique dress, a small house, a bridge, and even toys. Why buy new toys when you can buy a 3D printer and print your favourite Pokemon - the joke emphasised the importance of prototyping applications.

Marek Węglowski also discussed the financial aspects of using innovative production methods, as well as legal aspects and regulations. In subsequent presentations, the experts brought together for the Seminar learned about issues related to additive technologies and new materials for 3D printing. Marek Węglowski also explained the importance of Silesia Smart Systems - Digital Innovation Hub;

Jarosław Gazdowicz from the Upper Silesian Institute of Technology presented material tests of products made using additive methods. The next presentation by Tomasz Garniec, representative of Meltio, a company that produces laser metal deposition technology in the wire form discussed a new approach to metal additive manufacturing using welding wire. The speaker explained why metal 3D printing is easy, cheap, and safe, and presented the Wire Laser Metal Deposition technology and MELTIO solutions.

Prototyping methods were presented by experts from the Upper Silesian Institute of Technology; Piotr Śliwiński discusses rapid prototyping based on an electron beam, Michał Urbańczyk cast light on the laser beam process, and Tomasz Pfeifer - arc methods.

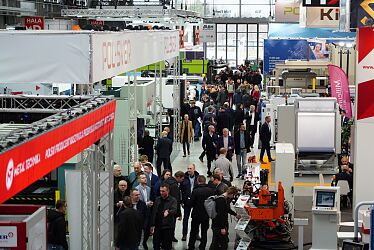

You can see the latest rapid prototyping machines at the Industrial Spring at Targi Kielce. The event continues until Friday, 22 March.

/MŚ/