News

ENGEL joins Plastpol 2025 with solutions that increase production efficiency

ELECTRIC e-mac: Higher productivity per unit area also in cleanroom applications

The highly precise, fully electric e-mac machine will be prominent at the ENGEL stand at the Plastpol trade fair. Machines of this series are available in tonnage ranges from 50T to 500 T. The device on show is equipped with the ENGEL cleanroom package, presenting an application for the medical sector; the compact e-mac series now saves space when producing medical parts in cleanrooms. Multi-cavity moulds require high precision and fast injection, and the latest generation of injection units provides both. The efficiency and compactness of the electric injection moulding machines from the e-mac series mean not only cleanroom production, but also real potential in a wide range of applications – from electronic connectors and housings, through thin-walled packaging, to technical parts requiring high precision, e.g. plastic gears.

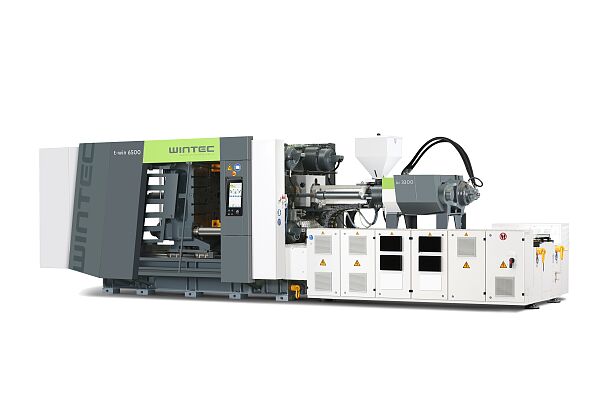

WINTEC t-win: Economical double plate machine

Wintec is the second injection moulding machine brand in the ENGEL Group to be presented at the Plastpol trade fair.: Twin-platen injection moulding machines are particularly popular for single-component injection moulding, which does not require any non-standard technologies but places high demands on quality and process repeatability. The range of applications includes household appliances, technical moulding and the automotive industry. Wintec machines are developed in Europe and manufactured in China; the Changzhou production plant is linked to the ENGEL Group's global quality management system. The t-win series servohydraulic double platen machines are available with clamping forces from 450 to 2,400 tons and are equipped with energy-saving Servowin servohydraulics as standard.

A perfect duo: ENGEL and TMA Automation

At the Plastpol, ENGEL will also be presenting an automation station perfectly tailored to the specific application. The production cell consists of standard automation components, including a robot, conveyor and safety barriers from ENGEL Automation, as well as individually tailored automation components from TMA Automation, the local Polish subsidiary of ENGEL Automation, which in this case supplies a sorting device, a gripper for inserting inserts and removing finished parts, as well as assembly automation and vision inspection.

Innovative service tools

The company specialists join the Plastpol expo to provide information on the wide service offer of the CSD Engel Polska department addressed to users of injection moulding machines and robots. When it comes to service, ENGEL focuses on prevention and anticipation; therefore, in addition to the standard CARE service offer, the injection moulding machine manufacturer will present digital solutions such as the iq family of programs. The latest are the IQ process observer and iQ hold control tools.

Industry representatives will find presentations by ENGEL and many producers and suppliers of raw materials during the 29th International Fair of Plastics and Rubber Processing PLASTPOL, 20-23 May in Targi Kielce. Tickets for visitors are available on the website plastpol.com

/MŚ/