A TiQ 2 3D printer will demonstrate additive manufacturing of workpieces and manipulator grippers are to be presented. ARBURG experts will explain how customers can further increase their production efficiency using digital services such as system management via the ALS host computer and the arburgXworld customer portal.

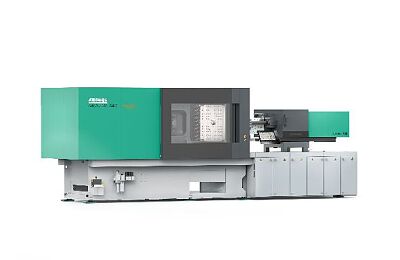

Electric ALLROUNDER injection molding machine produces drinking cups

Plastpol 2025 is the showcase for the production line for high-quality drinking cups made of transparent PC - a rational and sustainable alternative to glass and disposable items. The electric ALLROUNDER 570 A injection moulding machine produces 0.5-litre cups in a cycle time of around 60 seconds. The exhibit is equipped with numerous supporting functions that ensure high production efficiency and part quality; MULTILIFT SELECT 6 linear manipulator takes over the manipulation, while the collaborative manipulator (cobot) outside the production cell places small gifts in the cups and then hands them over to trade fair visitors.

ALLROUNDER hybrid injection molding machine produces spinning tops

The other injection moulding machine presented at the Plastpol trade fair is the hybrid ALLROUNDER 470 H “Premium,” which produces PP spinning tops as gifts for trade fair visitors in a cycle time of approximately 62 seconds. The manipulation of the moulded parts is carried out using the MULTILIFT SELECT 8 linear manipulator.

TiQ 2 to enter the world of additive manufacturing

The TiQ 2 filament printer for personalized series production will demonstrate 3D printing of end-of-arm tooling (EOAT), fixtures and other work tools in Kielce; this entry-level device is particularly suitable for everyday use in industrial environments and injection molding production, and processes fiber-reinforced filaments using Fused Filament Fabrication (FFF) technology, creating, for example, strong suction cups and mechanical grippers.