MSPO (2-5.09.2025)

33rd International Defence Industry Exhibition MSPO

OMNI3D Sp. z o.o.

- ul. św. Michała 43, 61-119 POZNAŃ, Poland

- sales@omni3d.com

- www.omni3d.com

Description

As a leading Polish manufacturer since 2013 and NATO-listed supplier (NCAGE N9BT1H), OMNI3D delivers industrial 3D printing solutions for the defense, railway, manufacturing, and industrial sectors.

We specialize in robust, autonomous production systems that integrate both FDM and LPBF technologies to provide superior flexibility and performance.

Our Core Offerings at MSPO:

TFU20 Tactical Unit: The TFU20 is our flagship containerized 3D printing lab. This field-ready unit provides full autonomy for producing spare parts and tools, eliminating logistical delays. It's designed to be easily transported by land, sea, or air, ensuring a rapid and discreet deployment in any environment.

FDM Printing: Our large-format industrial FDM printers are ideal for durable, high-temperature components. We support advanced materials like PC HL2, Nylon GF, and composites, with applications compliant with NATO AQAP and EN 45545 standards.

LPBF Metal Printing: In partnership with industry experts, we offer metal 3D printing for high-precision components. Our solutions use aluminum, stainless steel, and titanium to produce complex parts with properties equivalent to machined ones, supporting critical systems in aviation and military hardware.

OMNI3D provides a complete solution, including needs assessment, training, and ongoing support. We are a trusted partner to the Polish Armed Forces and key players in the defense industry.

Download our White Paper on Defense Case Studies: https://shorturl.at/iIPI6

Visit us at MSPO 2025: Hall Z, Stand 7Z53

Products

Omni3D Cooling System™ – active extruder cooling for use in heated chambers.

Filament Flow Control™ – ensures dimensional repeatability.

Air Circulation™ – maintains uniform internal temperature.

Omni3D Head Leveling Control™ – automatic measurement of Z-axis offset between extruders.

Platform Autoleveling™ – automatic bed leveling.

Power: 230 V, 2.2 kW, 190 kg.

Technical specifications:

Working volume: 500x500x500 mm (125 dm³), allowing for the printing of large parts or multiple smaller parts simultaneously.

Chamber: enclosed, actively heated to 140°C, platform to 180°C, with built-in filament dryer (1.75 mm).

Head: 2 heads with electronic lifting system, max temp 500°C, 0.4 mm nozzle (options: 0.6/0.8 mm).

Accuracy: Positioning +/- 1.56 µm (theoretical), parts +/- 0.15 mm or +/- 0.15% (dependent on geometry).

Drive: Ball screws on X, Y, Z axes with encoders, print speed up to 120 cm³/h.

Systems: Omni3D Air Circulation™ (uniform temperature), Platform Autoleveling System™ (automatic leveling), Cooling System™ (dimensional precision), Filament Flow Control™ (flow control), Head Leveling Control™ (head height calibration).

Filtration: CARBON+HEPA (optional).

Control: 10.1" touch screen, connectivity: SD, Ethernet, WiFi, USB. Simplify3D software, support for .stl, .obj, .3mf, .gcode.

Power supply: 230V/50Hz (option 110V/60Hz), max. 2.2 kW.

Technical Specifications:

Working space: 500x500x500 mm (125 dm³), for large components or serial printing of smaller parts.

Chamber: Closed, insulated, heated to 220°C (platform up to 220°C), with built-in filament dryer (1.75 mm).

Head: 2 heads with electronic lifting, max. temp. 500°C, nozzles 0.4/0.6/0.8 mm.

Precision: Dimensional +/-0.2% (min. +/-0.2 mm), printing speed up to 155 mm/s.

Drive: Ball screws on X, Y, Z axes with encoders.

Systems:

Omni3D Air Circulation™: uniform temperature in the chamber.

Omni3D Cooling System™: dimensional precision.

Omni3D Filament Flow Control™: print repeatability.

Omni3D Platform Autoleveling™: automatic table calibration.

Omni3D Head Leveling Control™: head height control.

Filtration: CARBON+HEPA (optional).

Control: 10.1" LCD screen, connectivity: SD, Ethernet, WiFi, USB. Simplify3D software, support for .stl, .obj, .3mf, .gcode.

Power supply: 230V/50Hz (3-phase), max. 10 kW.

3D printers:

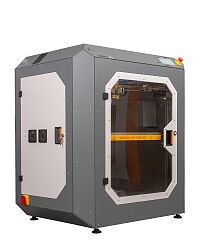

Omni Pro: Volume 500x500x500 mm, chamber heated to 140°C, automatic leveling, inspection reports. For general-purpose materials.

Omni Pro HT: Nozzle up to 500°C, chamber up to 220°C. For engineering plastics (PEI, PEEK, PEKK with carbon/glass fiber).

Omni Tech: Multimaterial, supports ESD-safe, flame-retardant plastics (railroad standards) and ABS, ASA, TPU, PC/ABS.

Polish printers ensure reliability under military conditions.

Container equipment:

Technical section: power generator, ventilation with HEPA filter, dehumidifier, air conditioning, heating.

Hydraulics: To stabilize the container.

Storage: Filament cabinets, material dryer, soldering station, batteries, chargers.

Materials: Plastics ranging from basic (ABS, TPU) to specialized (PEEK, PEKK), ESD-safe, fireproof. Software modules support file encryption, inventory management and reporting according to procedures.