MSPO (2-5.09.2025)

33rd International Defence Industry Exhibition MSPO

Łukasiewicz - Instytut Ceramiki i Materiałów Budowlanych

- ul. Cementowa 8, 31-983 Kraków, Poland

- 126837911

- info@icimb.lukasiewicz.gov.pl

- www.icimb.lukasiewicz.gov.pl

Description

With a wide range of authorizations, including the status of Notified Body of the European Union No. 1487 and accreditation by the Polish Center for Accreditation, the Institute confirms its credibility and professionalism in the field of research and innovation. It specializes in research on fire safety and the insulation and acoustic properties of building materials, which contributes to the development of safe and efficient construction technologies. In addition, the Institute's research work contributes to a better understanding of the fire properties of facades and is key to improving fire safety, thereby supporting the sustainable development of the European building space.

Products

Material: silicon nitride (Si₃N₄)

Main properties:

high resistance to temperature and thermal shock

low specific weight: 3.21 g/cm³ (more than twice as light as steel alloys)

Advantages:

reduction in the weight of rocket components

increased rocket range

potential for increased payload

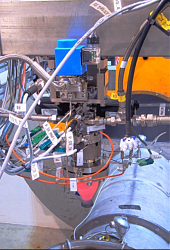

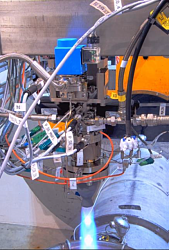

Test results: a silicon nitride combustion chamber tested in monopropellant mode achieved stable thermal parameters at temperatures up to 1200 K

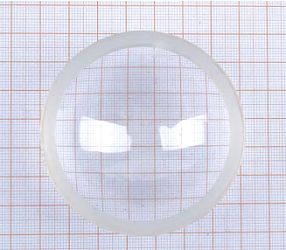

YAG application: optical elements – windows, lenses, prisms, infrared components, laser-active ceramics

Spinel application: standard and infrared ballistic shields, including thermal imaging camera shields in combat vehicles

Properties:

high transparency in the infrared range

high mechanical resistance

increased thermal resistance

weight reduction of components compared to traditional glass

Benefits: increased durability and protection of optoelectronic components while reducing the weight of the structure

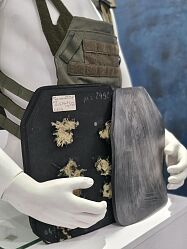

Material: silicon carbide (SiC), aluminium oxide (Al₂O₃), silicon nitride (Si₃N₄)

Ceramic layer thickness (SiC): 8 mm

Surface area: approx. 670 cm²

Weight: approx. 1550 g (2.5 times lighter than steel inserts of the same size)

Protection classes: K4 and K5A according to PN-V-87000:2011

Application: bulletproof vests for the military and special services; armour for combat vehicles

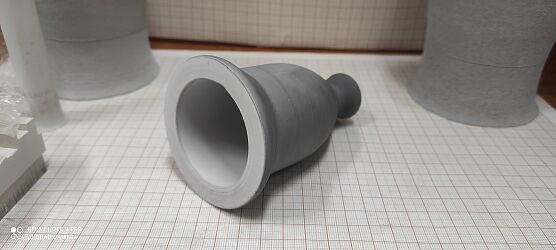

korpus w kształcie walca (tworzywo)

denko (tworzywo)

wkładka ceramiczna (walec z tlenku glinu)

walec z materiałem wybuchowym (montowany oddzielnie lub w całości)

Zalety konstrukcji:

długa żywotność magazynowa (ceramika nie ulega starzeniu)

możliwość wymiany materiału wybuchowego po upływie okresu przydatności

prostota montażu i demontażu

Warianty ceramiczne:

A – grubość 5 mm

B – grubość 10 mm

C – grubość 15 mm