MSPO (2-5.09.2025)

33rd International Defence Industry Exhibition MSPO

GyeongNam TechnoPark(GNTP)

- dae-ro 18beon-gil, 51395 Changwon City, South Korea

- +82-55-259-7031

- seonil.hwang@gntp.or.kr

- www.gntp.or.kr

Description

- Implementing export support programs such as overseas marketing

Products

The tip has markings such as “LOW,” “FULL,” and “COLD IDLE,” enabling quick visual confirmation of whether the oil is within range. To measure, insert the dipstick fully into its port, remove it, and compare the oil mark with the reference lines. Readings vary with operating or idle states and temperature.

Built for extreme military conditions—vibration, shock, and temperature changes—the dipstick uses high-strength metal with a corrosion-resistant finish to maintain shape after repeated use. Wear- and heat-resistant markings ensure long-term readability.

This tool provides fast, accurate oil status checks, helping extend service life and ensure reliable KM9 operation.

It has a central fastening bolt and multi-layer disc structure. The disc lifts during intake to open the passage and seals instantly during discharge to prevent backflow. Accurate machining, surface finish, and proper materials are essential for fast response and tight sealing.

It can be made in grey cast iron, carbon steel, or stainless steel, and customized for pressures from 10 to 300 bar. All materials are treated for marine environments, resisting corrosion and wear. A uniform opening pattern stabilizes flow, reduces noise, and improves efficiency. Optimized strength and geometry maintain performance over long-term use, ensuring durability, reliability, and efficiency in demanding naval conditions.

Built to endure the harsh environment of naval operations, it can be custom-made in various materials and designs per customer requirements. Special heat treatment enhances wear resistance and minimizes deformation during repeated cycles, while optional coatings improve corrosion protection.

Manufactured through precision CNC machining, dimensional inspection, surface finishing, and assembly, each unit passes strict testing for accuracy, strength, and durability, ensuring consistent performance in high-rate, continuous fire. This reliability makes it essential for maintaining operational safety and readiness.

Operation: When internal pressure reaches the set value, the spring is compressed beyond its limit, lifting the valve disc and opening the passage. Air is discharged until pressure returns to a safe range, then the disc reseats to seal the flow path.

Construction: The valve has a brass housing for corrosion resistance and sealing, and a stainless steel body for strength and wear resistance under high loads and repeated cycles. A threaded connection allows easy installation and removal, while a top adjustment knob enables precise pressure setting.

Performance: Built for marine and industrial use, it resists corrosion, wear, and deformation under long-term high-pressure operation. Available in various specifications for 10–300 bar, it ensures overpressure prevention, equipment protection, and safe operation in demanding environments.

1) 20kWh BSA

- Nominal voltage : 350.4V

- Capacity : 60Ah

- Dimensions : 1205(W)*900(D)*200(H) mm or less

- Weight : 170.5 kg

- Environmental Conditions : MIL-STD-801G

( High/Low-Temperature Operation, Vibration ,Shock)

- EMI : MIL-STD-461F

2) 40kWh BSA

- Nominal voltage : 350.4V

- Capacity : 120Ah

- Dimensions : 2030(W)*900(D)*200(H) mm or less

- Weight : 320 kg

- Environmental Conditions : MIL-STD-801G

( High/Low-Temperature Operation, Vibration ,Shock)

- EMI : MIL-STD-461F

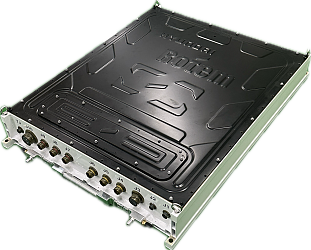

Input Voltage: 80-265 V AC

Input Frequency: 47-65 Hz

Output Voltage: 28 V DC ± 0.5 V DC

Weight: 17.7 kg

Dimensions: 540.3(W) x 86.4(D) x 431.8(H) mm or less

Environmental Conditions: MIL-STD-810G

(High-Temperature Storage, High/Low-Temperature Operation, Humidity, Vibration, Shock)

EMI: MIL-STD-461F

(CE102, CS101, CS114, CS115, CS116, RE102, RS103)