News

AICON 3D SYSTEMS PUTS ITS NOVELTIES AT THE CONTROL-TECH

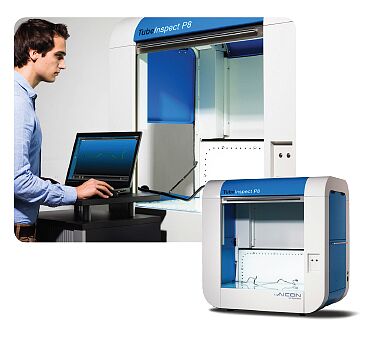

AICON 3D Systems will use the upcoming Control-Tech expo as the showcase to present, among others, the innovative optical test device TubeInspect P8; high precision and modern design allow to perform control of serial production. The measurement utilise the photogrammetry principle.

This test-device is used for a rapid quality control and the geometry of curved elements with round cross-sections (pipes, cables, wires). This device allows for measurement time of about 3 seconds; the classic-type solutions like coordinate-measuring machines and measuring arms equipped with attachments require a few or a few dozens of minutes.

What is more, the TubeInspect allows to do away with and replace mechanical the rapid verification gauges for bent shapes as they are expensive to manufacture and maintain.

Having completed the verification, the system automatically performs analyses and makes it possible to calculate bending corrections and transfer the data over the network to the bender. The statistics module contained in the instrument control software -BendingStudio- allows to monitor production process and predict the errors accumulation in the bending area.

BendingStudio also allows to simulate adjustments and to visualise their impact on other parts of the product.

The AICON 3D Systems company's offer will be presented at the E-43 stand!