TEST-STOM (28-31.03.2023)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

SPES3D SPÓŁKA Z OGRANICZONĄ ODPOWIEDZIALNOŚCIĄ

- ul. Bierutowska 57-59, 51-317 WROCŁAW, Poland

- 882 191 184

- spes3d.pl

Description

For the production of polymer parts, we use

the MJF (Multi Jet Fusion) technology and the HP MJF system.

This system provides high dimensional accuracy and repeatability of the produced elements while maintaining excellent strength parameters. The MJF technology is the perfect alternative to injection molding for short and medium-series production.

POLYMERS:

PA 11,

PA 12,

TPU.

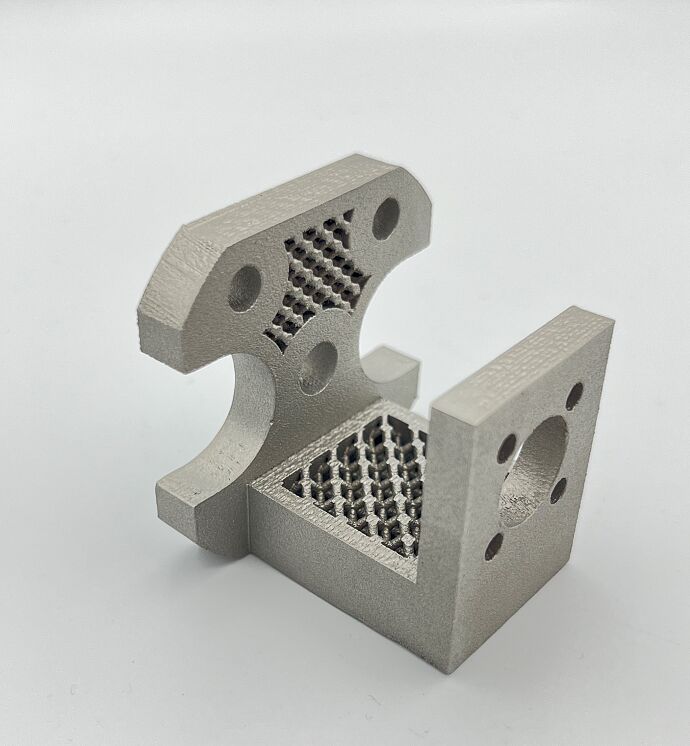

For the production of metal alloy parts, we use

the L-PBF (Laser Powder Bed Fusion) technology and the MetalFAB system. This is the latest generation system for metal powder welding, previously unavailable on the Polish market. Metal parts produced in this technology have strength properties equal to

parts produced by conventional methods.

METAL ALLOYS:

Stainless steel 316L (1.4404),

Tool steel M300 (1.2709),

Aluminum AlSi10Mg,

Titanium Ti6Al4V Grade 23,

Inconel 718.

ENGINEERING SERVICES

Our engineers are at your disposal. We have experience in prototyping, modeling, such as based on technical drawings or reverse engineering based on a supplied detail. We also offer FEM and CFD simulation services and engineering advice.

3D SCANNING

No project is a problem for us, advanced 3D scanners allow us to recreate every detail of the elements entrusted to us. We will develop the appropriate project taking into account the production process so that you get the product you need.

INJECTION MOLDING

Our machine park is equipped with high-class electric injection molding machines allowing for mass production. Thanks to our experience and business approach, we will meet even the greatest challenges.

Download

-

Spes3d.pdffile size: 2.40 MB