PLASTPOL (20-23.05.2025)

29th International Fair of Plastics and Rubber Processing PLASTPOL

Fado Sp. z o.o.

- UL. SOLNA 7A, 85-862 BYDGOSZCZ, Poland

- 523707979

- www.coolingcare.eu

Description

CoolingCare is a Polish brand specializing in the production of advanced machines for the diagnostics, maintenance, and cleaning of cooling channels in injection molds, die-casting molds, and other types of heat exchangers. These machines are the result of over six years of research conducted by FADO Sp. z o.o., a company with more than 35 years of experience in designing and manufacturing injection molds and inserts with conformal cooling.

Innovative Cavitation Cleaning Technology

At the heart of CoolingCare’s technology lies a patented cavitation cleaning method, which effectively removes scale and contaminants from cooling channels without the need to disassemble the mold. By utilizing cavitation, the cleaning process is both fast and safe for tooling, while minimizing the use of aggressive chemical agents.

A Wide Range of Machines Tailored to Different Needs

CoolingCare’s product portfolio includes four machine series:

CP Series: Compact and cost-effective machines ideal for facilities with a small number of molds. Despite their competitive pricing, they use the same cavitation cleaning technology as higher-end models.

CM Series: Versatile and configurable units that can be tailored to the user’s specific needs. Equipped with a high-capacity diaphragm pump and a bidirectional cleaning function that significantly speeds up the process.

CS Series: Compact machines designed for users with high demands. The CS2 model offers all the key features of the flagship CA series, excluding the mold database and OPC UA communication. Available in a dual-circuit version with semi-automatic operation mode.

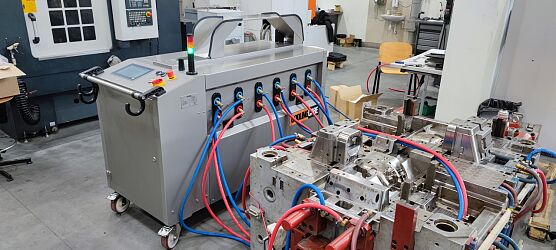

CA Series: The most advanced, fully automated systems developed for modern plastics processing. These machines feature intelligent cleaning modes, six independent cleaning sections, and cleaning result export capabilities, enabling predictive maintenance strategies.

Services and Customer Support

In addition to selling equipment, CoolingCare offers a wide range of services, including:

* Product presentations and machine demonstrations

* On-site mold cleaning services

* Short- or long-term equipment rental

* Training for operators and technical staff

Thanks to a global network of distributors, CoolingCare provides technical and service support worldwide.

If you’re looking for reliable solutions for cleaning cooling channels in molds, CoolingCare offers innovative technology and comprehensive support that will enhance the efficiency and longevity of your production tools.

Download

-

coolingcare-2024-EN-web.pdffile size: 4.38 MB

Products

* Hydromechanical hybrid cleaning process based on the cavitation phenomenon

* Autonomous cleaning mode operating until stable reference flow rates are achieved

* Cleaning time for each channel is defined independently; the process continues as long as necessary

* Channel drying after cleaning

* Option to export mold cleaning results

* Cleaning history stored in the machine’s internal database

Diagnostics

* Leak and flow-through test using compressed air

* Automatic diagnostics with unattended transition to cleaning mode

* Flow rate measurement with reference value comparison from the database

* Drying of channels with compressed air after diagnostics

Maintenance

* Flushing of channels with tap water

* Optional corrosion inhibitor application for added protection

Additional Functions

* Tank filling and draining function

* Suction filter clogging sensors

* Modifiable parameters and operation algorithms

* Operating hours tracking for individual pumps and pulsators

* Monitoring of cleaning medium operating hours

* Remote software updates

Configurable with 2 to 4 independent cleaning circuits

Each circuit equipped with a dedicated diaphragm pump and cavitator

Enables simultaneous cleaning of multiple cooling channels

Advanced monitoring of flow, pressure, and temperature

Manual and semi-automatic modes with programmable parameters

Data logging and automatic report generation

Flexible setup tailored to the specific needs of the plant

2 independent cleaning circuits for simultaneous cleaning of two channels

Semi-automatic operation with flow direction reversal option

User-friendly operation via intuitive control panel

Cavitation generated by dedicated pump for effective deposit removal

Real-time monitoring of pressure and flow

Compact dimensions and mobile design

Ideal for small and medium-sized facilities

Patented hydromechanical cleaning method utilizing the cavitation effect

Two independent cleaning sections with dedicated supply pump and cavitation generator

Reversal of cleaning media flow direction

Built-in tutorial mode with user-friendly interface guiding the operator step by step

Flow rate measurement (dedicated impeller pump with flowmeter and reservoir)

Precise real-time liquid level monitoring using an ultrasonic sensor