INDUSTRIAL SPRING 2025 (25-28.03.2025)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

ANCA Europe GmbH

- Im Technologiepark 15, D-69469 WEINHEIM, Germany

- 496201846690

- WWW.ANCA.COM

Description

ANCA is a market leading manufacturer of CNC grinding machines. It was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. With over 1,200 employees worldwide in the CNC machines, drives & controls and manufacturing solutions divisions, its own software and automation solutions, ANCA is characterised by a high level of vertical integration. CNC grinding machines from ANCA are used to manufacture precision tools for mechanical engineering, power generation, woodworking, automotive engineering, aerospace, electronics and medical technology. They are also used to manufacture components in medical technology, aerospace and power generation.

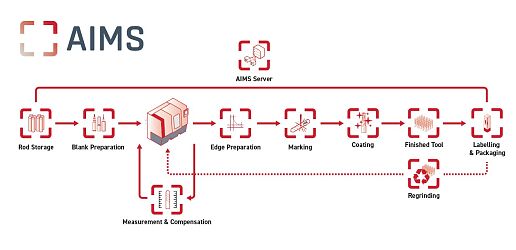

A passion for technology and innovation, experience and expertise in various industries, and the added value of high vertical integration offer ANCA users advantages in terms of productivity and quality. The current developments focus on efficient production and quality optimisation through integrated manufacturing. The ‘ANCA Integrated Manufacturing System’ (AIMS) is an automated system that represents ANCA's leading position in the areas of connectivity and digitisation.

ANCA Europe covers local requirements in the region. The company has its headquarters and technology centre in Weinheim, with expert teams for service and sales, product management, engineering, application technology, customer training, finance and administration. Customer demonstrations, project acceptance and events are regularly held at the technology centres in Weinheim and Coventry. Our experienced team of technical experts at ANCA Italia Srl supports our customers in Italy in achieving best quality and profitability in precision manufacturing. To provide customers with local support, ANCA also has subsidiaries and sales and service teams in England, France, Israel, Poland, Spain and Türkiye.

Download

-

Machine-table-A3-digital.pdffile size: 1.43 MB

Products

At Stom, ANCA will showcase the benefits of two technology experts working together for the success of manufacturers. CemeCon, coating technology experts from Germany, will be present at the ANCA booth, showcasing their innovations and advising visitors.

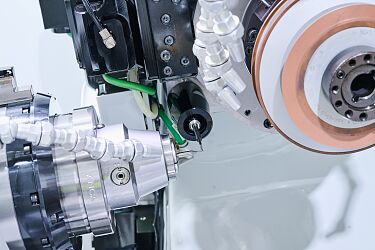

- Shorter setup time

- Less waste

- No need to remove the tool from the machine

- Increased productivity

- Statistical process control cycle available

- Laser permanently mounted inside the machine

Another important feature is the ability to measure total tool runout and compensate for it in the iGrind software. When rotating a face mill, it is important that each of its teeth cuts the material at the same point along the workpiece to ensure greater tool life and machining efficiency.

Each tool within a batch can be measured AND compensated for runout, ensuring that the entire batch is within a tolerance of 0.002 mm. This is another solution to ensure that the last face mill is of the same quality as the first.

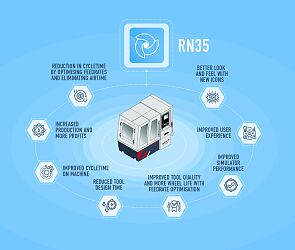

Average productivity gains of up to 20% through advanced features and functions, optimizing feed rates, improving cycle time and surface finish, and extending wheel life.

New features include integration of material removal rate calculations, enabling manufacturers to automatically set parameters for constant removal rates and reduce air time.

Statistical Process Control (SPC) software for statistical analysis and evaluation of characteristics of manufactured parts improves manufacturing processes.

Profile gouging further enhances the popular solid material flute function in ANCA's patented software.

Experts will present these and other updates to Stom visitors, as well as more exciting new developments in CIM3D simulation software.